ASTM A179 (ASME SA179) is a low-carbon cold-drawn seamless steel tube for use in tubular heat exchangers, condensers, and similar heat transfer applications.

ASTM A179 and ASME SA179 are two standards that are completely equivalent. For the sake of convenience, ASTM A179 is used below.

ASTM A179 is suitable for steel pipes with an outer diameter of 1/8″ – 3″ [3.2mm - 76.2mm].

Botop Steel is a seamless steel pipe stockist from China, offering you a large selection of high-quality ASTM A179/ASME SA179 cold-drawn seamless steel pipes.

We are dedicated to providing our customers with the highest quality products and services to ensure that your projects run smoothly. Choose Botop Steel, and choose a reliable partner.

We have already mentioned that the A179 is produced using the cold-drawn seamless manufacturing process. What are the specific processes involved in cold-drawn seamless manufacturing? Please see the following process flow chart.

In the ASTM standard, A556 also uses the cold-drawn seamless manufacturing process but is specifically for tubular water heaters. Those who are interested can find out more.

After the final cold drawing, the steel tubes are heat-treated at temperatures of 1200°F [650°C] or higher.

| Standard | C | Mn | P | S |

| ASTM A179 | 0.06-0.18% | 0.27-0.63% | 0.035% max | 0.035% max |

ASTM A179 does not allow the addition of other elements to the chemical composition.

The hardness of the steel tube must not exceed 72 HRBW (Rockwell hardness).

| Tensile strength | Yield strength | Elongation | Flattening Test | Flaring Test | Flange Test |

| min | min | in 2 in. or 50 mm, min | |||

| 47 ksi [325 MPa] |

26 ksi [180 MPa] |

35% | See ASTM A450, Section 19 | See ASTM A450, Section 21 | See ASTM A450, Section 22 |

Each pipe shall be subjected to a hydraulic pressure test or, if the buyer so stipulates, a non-destructive electrical test may be used instead.

The steel tube maintains pressure for at least 5s without leaking.

The test pressure is calculated using the following formula:

Inch - Pound Units: P = 32000 t/D

SI Units: P = 220.6t/D

P = hydrostatic test pressure, psi or MPa;

t = specified wall thickness, in. or mm;

D = specified outside diameter, in. or mm.

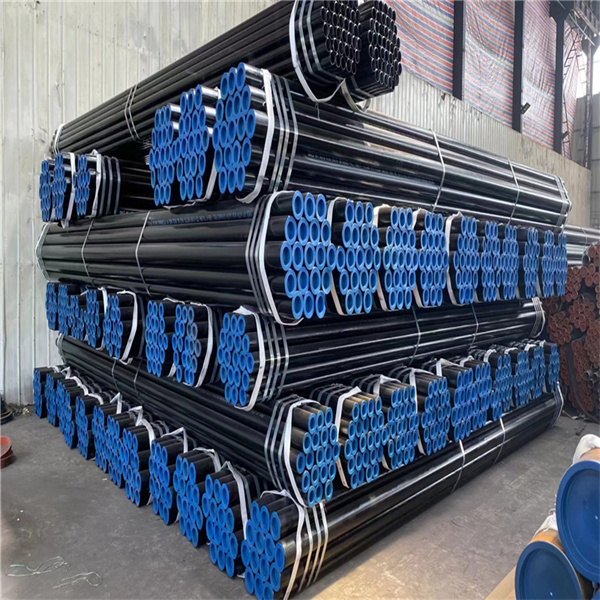

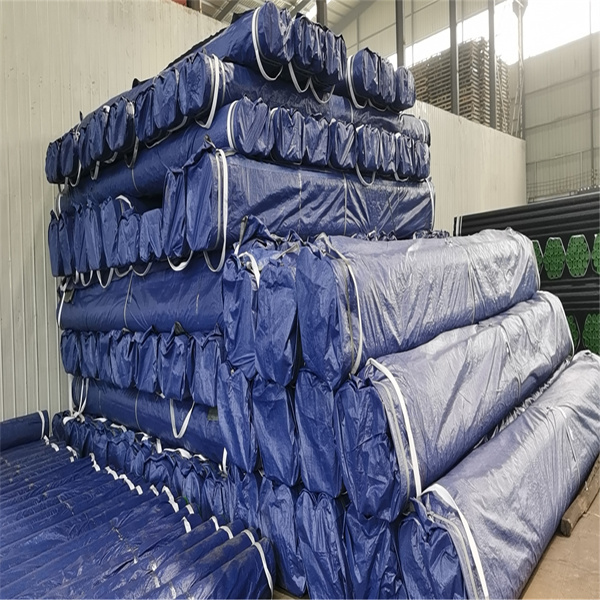

The following is a common A179 packaging, and customized packaging can also be provided according to project requirements.

Bare pipe, black coating ( customized);

6" and below sizes In bundles with two cotton slings, other sizes in loose;

Both ends with end protectors;

Plain end, bevel end;

Marking.